CVD-Diamond Coating Application

Product detail

Diamond coating

What is diamond?

The hardest naturally occurring substance in nature, with the chemical formula C,

is a crystal composed of carbon elements assembled in a tetrahedral structure.

Technical principle: The hot wire chemical vapor deposition is used, the reaction gas methane and hydrogen

passes through the high temperature tungsten filament, and is ionized into the group which is conducive

to the deposition of diamond, and the gaseous group is transported to the substrate with a

certain temperature, and then nucleates and grows on the substrate in the shape of an island,

and ultimately forms a diamond film on the surface of the substrate.

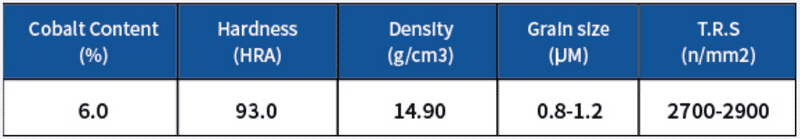

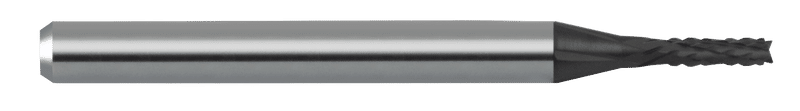

Diamond coated cutting tools are made of industry-advanced cemented carbide with sub-micron grains,

for high wear-resistant machining applications.

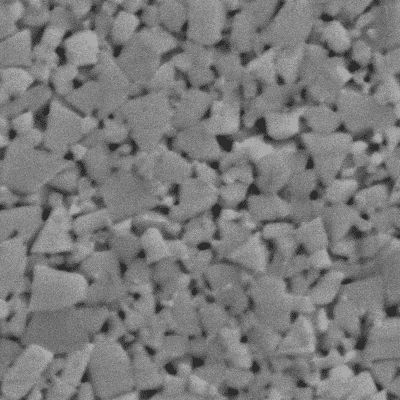

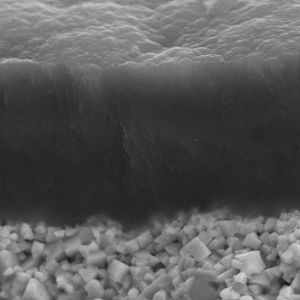

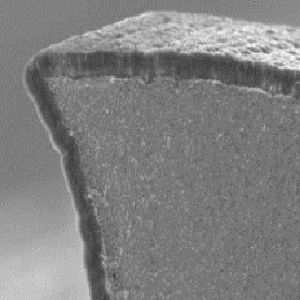

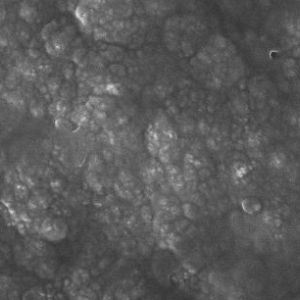

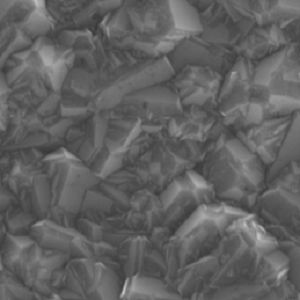

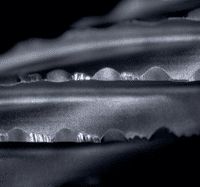

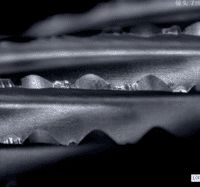

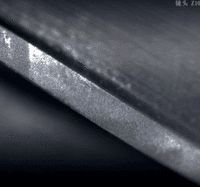

microstructure 10000×(the right)

Diamond coated cutting tools

Application Areas

Diamond coated series cutting tools are widely used in high frequency and high speed plate, ceramic plate, aluminum

substrate processing, and also suitable for carbon fiber plate, graphite mold, high silicon aluminum alloy processing.

extremely strong wear resistance, ultra-high processing life;

stable size of processed products, high processing quality;

fewer tool changes, high processing efficiency.

Ultra-fine nanocrystals, ultra-high hardness,Extremely high abrasion reistance

Excellent tool shape retention for fast and easy cutting

Effective inhibition of machining heat or sticky chips

Sub-Fine Grain Size Cemented Carbide,High wear resistance and toughness,Good coating adhesion

Better finish,Higher dimensional accuracy(0,-0.008)

normal coating(the left)ultra-fine nano CVD diamond coating(the right)

Application of diamond coating processing

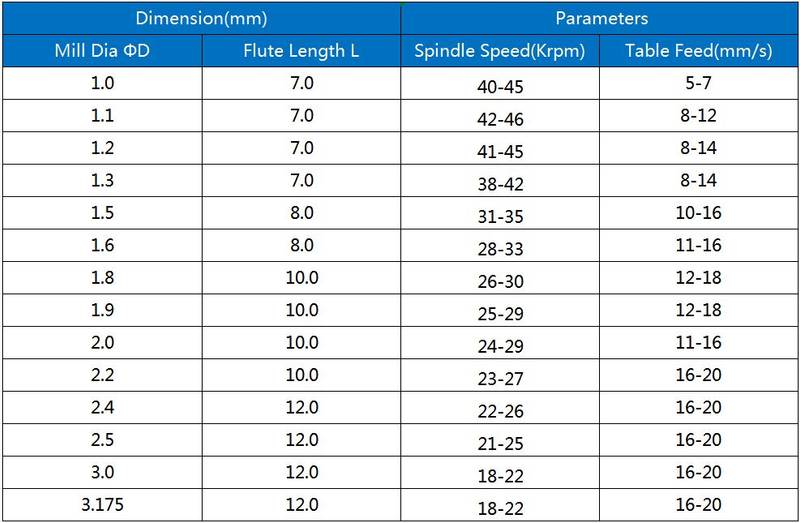

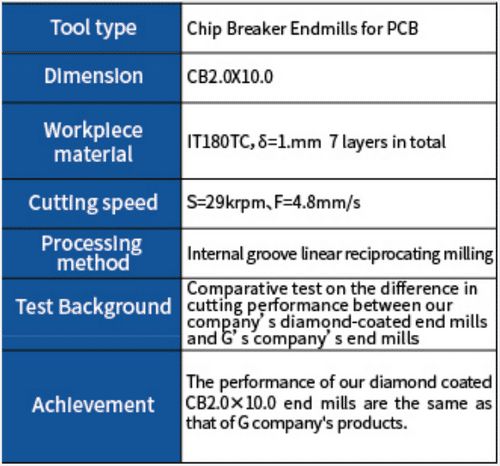

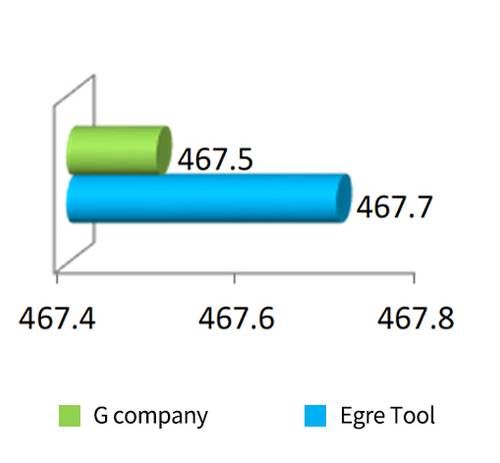

Application 1 CB2.0*10.0 diamond-coated end mills processing IT180TC plate cutting performance

Processing path(the left) EgreTooL(the middle)Company's(the right)

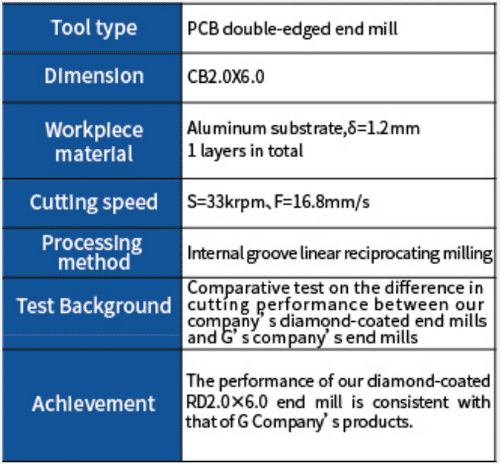

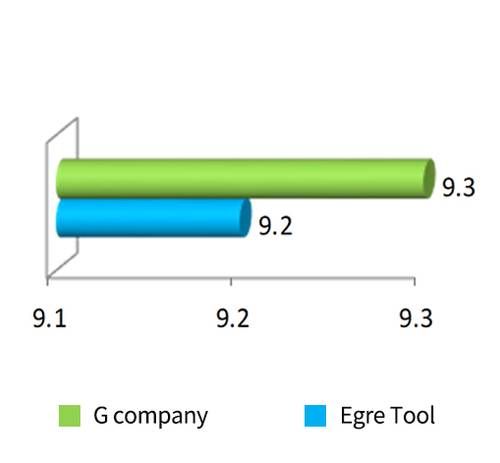

Application 2 Cutting performance of RD2.0*6.0 diamond-coated end mills in processing aluminum substrates

Processing path(the left) EgreTooL(the middle) Company’s(the right)

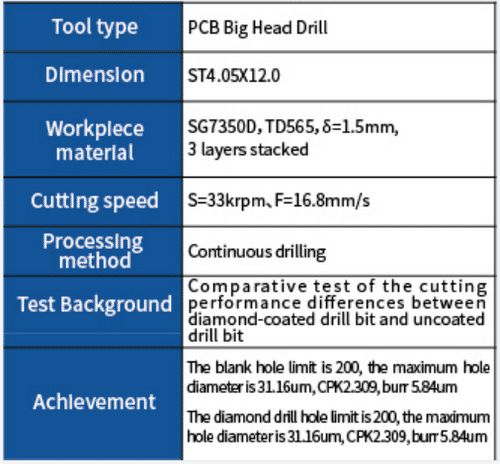

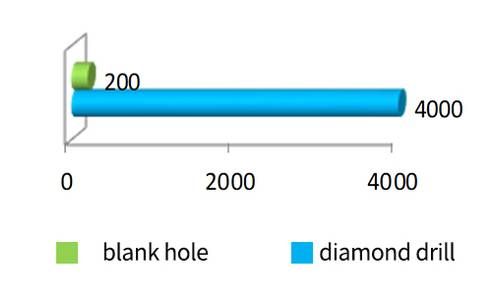

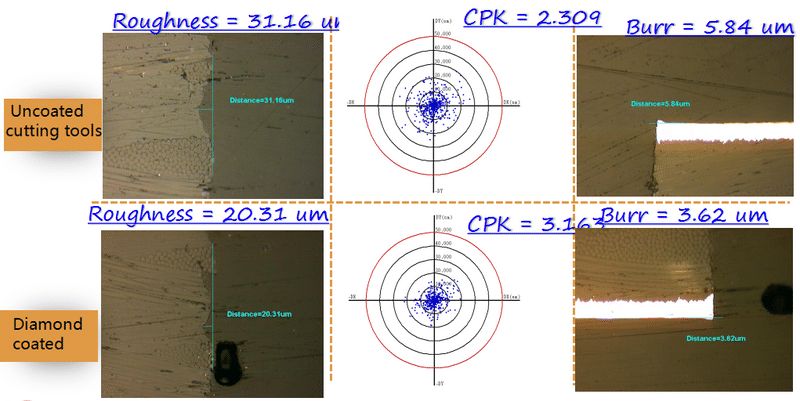

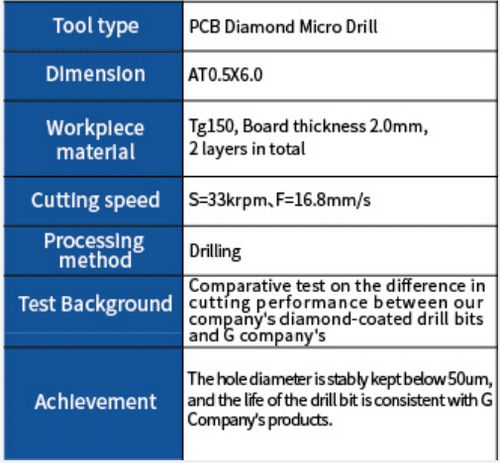

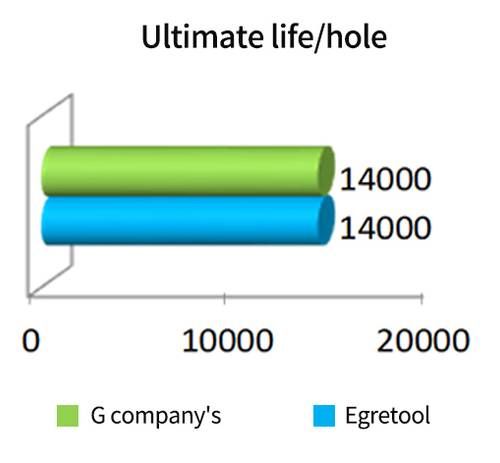

Application 3 Case study of diamond-coated drill bit processing of polymer plate

Application 4 Diamond coated drills for machining high speed plates