CVD- Diamond Coating Application(TAC/DLC)

Product detail

Diamond-like carbon coated cutting tools

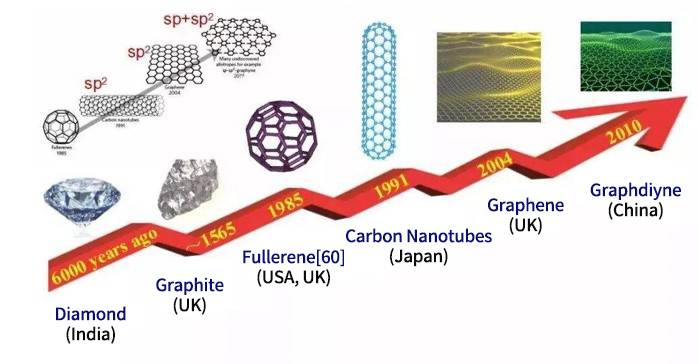

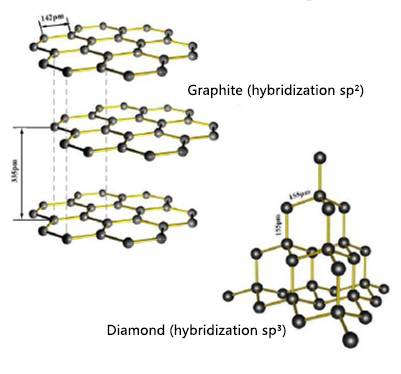

Material development of the element carbon in diamonds (different arrangements of atoms)

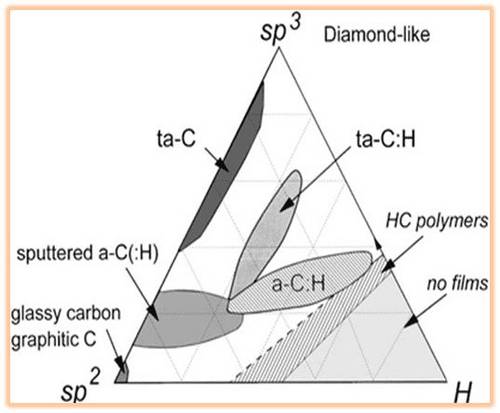

What is diamond-like carbon? (Amorphous carbon coatings containing more than 50% tetrahedral structure)

Soft enough to be used as a lubricant(the left)The hardest material in nature(the right)

Diamond-like carbon (DLC) coating

Technical principle: Combining arc ion plating and plasma-assisted chemical deposition technology, the target material

and process gas are ionized through arc ion plating technology first, and a Cr transition layer is deposited onto the

workpiece under bias acceleration to improve the film base bonding force, and then through plasma-assisted

chemical vapor-phase technology, the hydrogen-containing compounds are passed through to carry

out a glow discharge, and a DLC lubrication layer is deposited onto the workpiece under bias acceleration.

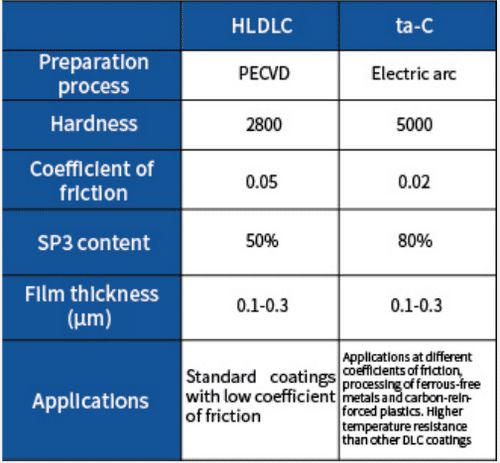

DLC and TAC performance distinction, micro-drilling coating TAC will be better than HLDLC

Characteristics of our DLC coating

Good surface finishment with Diamond-like Coating

Good chip removal, low cutting heat

Other DLC Coating(the left)Our DLC Coating(the right)

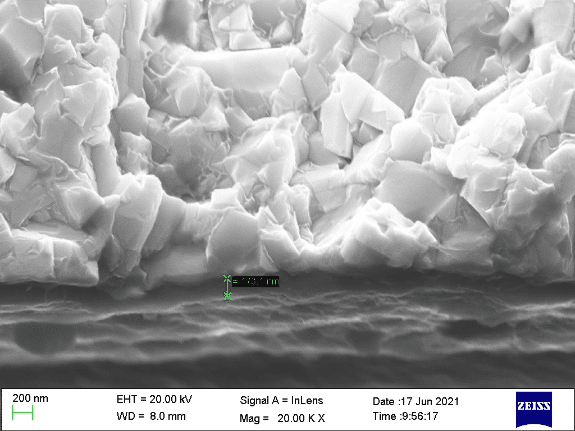

Excellent Adhesive Force

Cr Bottoming , Good Adhesive force

Coating Substrate Properties

Structural Constitution: C

Nano Hardness: 3300HV0.005

Max Temperature: 300°C

Friction Coefficient Against Steel: 0.05

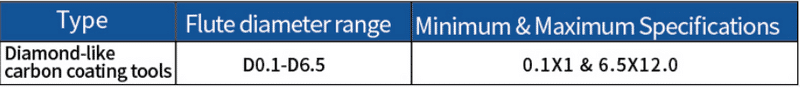

Diamond-like carbon coating tools

Uses: Enhance the wear-resisting and lubricating properties of the blade, molding and drilling of various

ordinary plates and environmental protection plates, especially suitable for high quality requirements of

the edge of the plate and high requirements of the hole roughness;

Advantages:It can strengthen the dust removal ability of micro cutting tools, and improve the life

of micro tools with very small diameter and large length-to-diameter ratio more obviously, with high

dimensional accuracy, high life, and excellent board edge quality.

Application Areas

DLC coated series tools are widely used in FPC flexible boards, package substrates, pure aluminum and

aluminum alloys, pure copper and copper alloys, etc. They can also be used in common single/double

sided boards, 5G communication boards, high speed boards, etc.

Application 1 DLC coated drill bit processing SEVER board

Application 2 DLC coated drill bit processing NB board

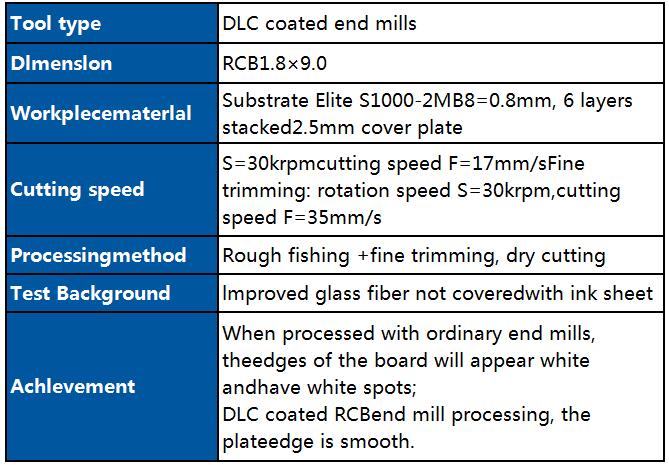

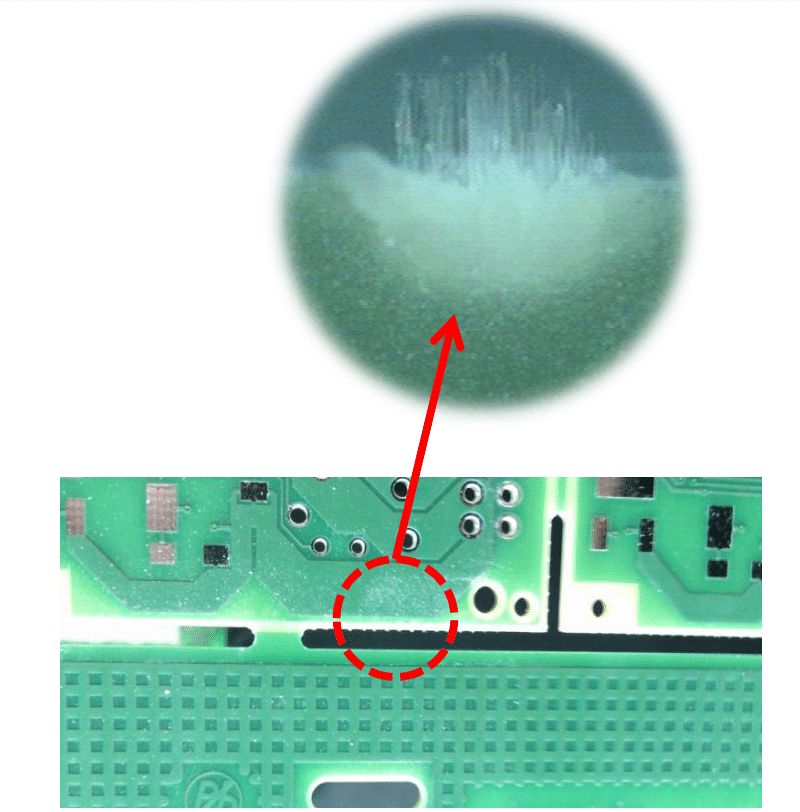

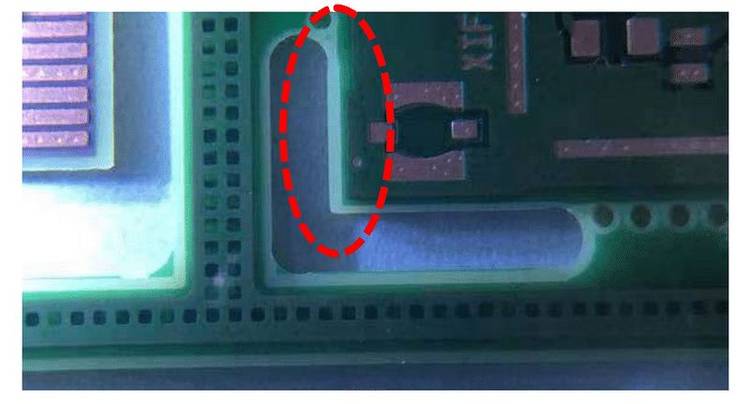

Application 3 DLC milling cutter processing case of plate not covered with ink