PVD Armor Coating Case

Product detail

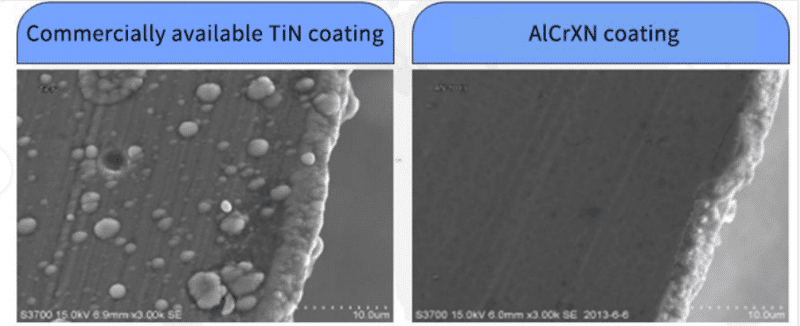

Armor Coating

Technical principle: the use of arc ion plating, the solid metal target ionization, and through the N2, a layer

of deposition on the surface of the tool, the deposition rate is fast, the coating adhesion is good,

the organization is dense, uniform, the coating on the complex shape of the workpiece coverage capacity.

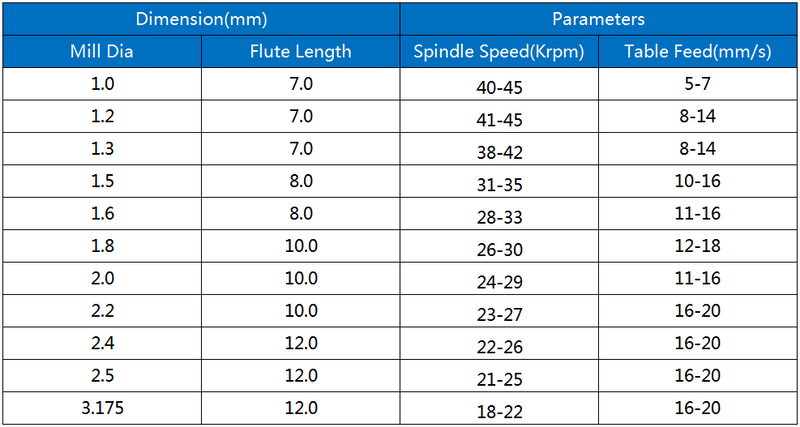

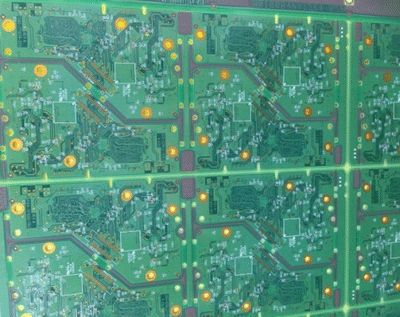

Introduction of our armor coated PCB cutting tools

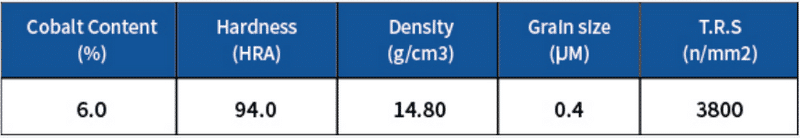

Armor coated cutting tools are made of industry advanced cemented carbide material, with

ultra-fine grain, excellent wear resistance, and compatible with good hardness and toughness,

suitable for high wear resistance processing occasions.

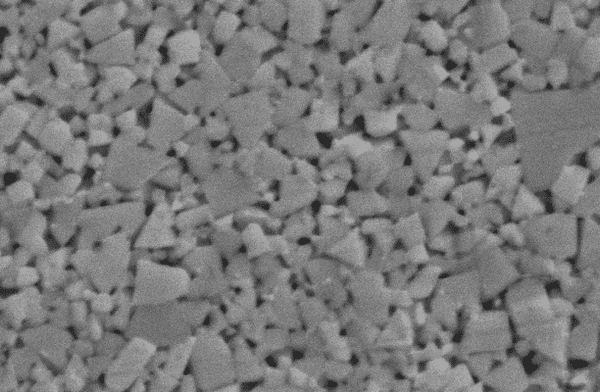

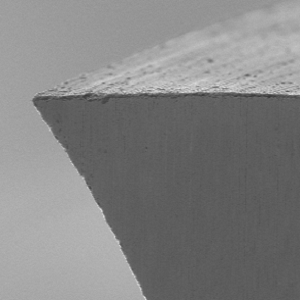

microstructure 10000×

Performance indicators

Cutting tools with armor coating series are widely used in the processing of all kinds of PCB panels.

PCB router with Armor-J coating, high hardness, perfect wear resistance ,super performance

withnew and advanced Armor-J coating.

AlCr-based armor coating with good surface finish;Good chip removal ability and less cutting heat generation

Sub-microfine cemented carbide,High abrasion reistance and toughness

High hardness: 94HRA

Better finish,Higher dimensional accuracy(0,-0.008)

Multi-layer high hard coating design,Super high heat insulation effect

Inhibit the wear and sudden chipping of the milling cutter edge

Excellent tool shape maintenance ability, providing light cutting

Effectively inhibit processing heat or sticky chips

The process of slowing down the diffusion wear

Ensure that the PCB has smooth edges

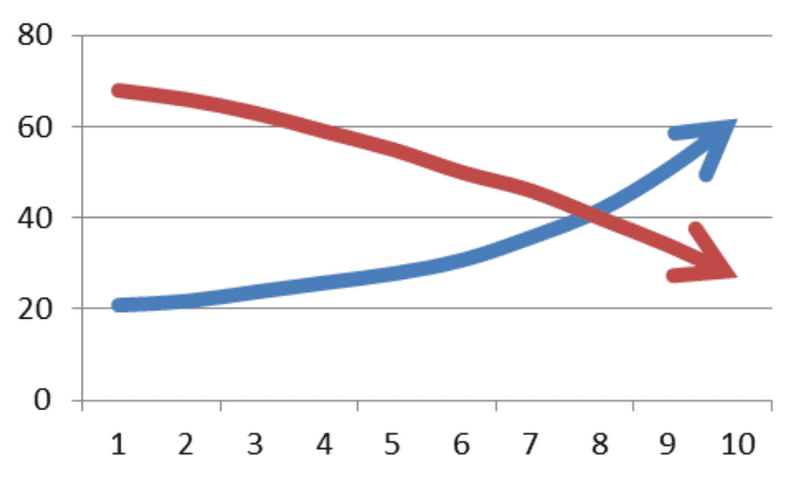

Armor coated milling cutter(the left)General coated milling cutter(the right)

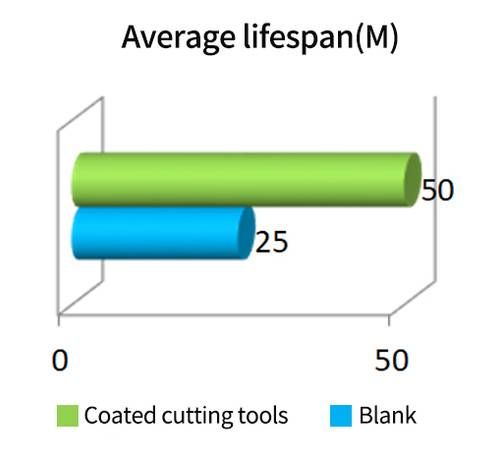

< High lifespan>

High durability, maintaining stable molding dimensions

Especially suitable for dredging copper clad laminates

The service life can be increased by 200% compared with ordinary PCB milling cutter

Armor coating processing application

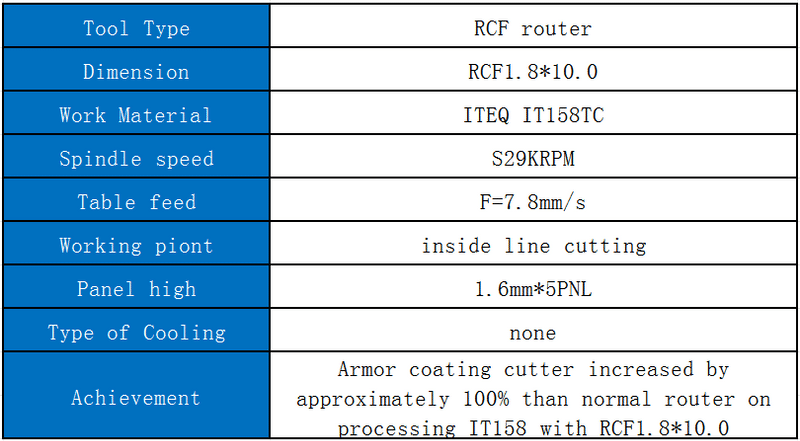

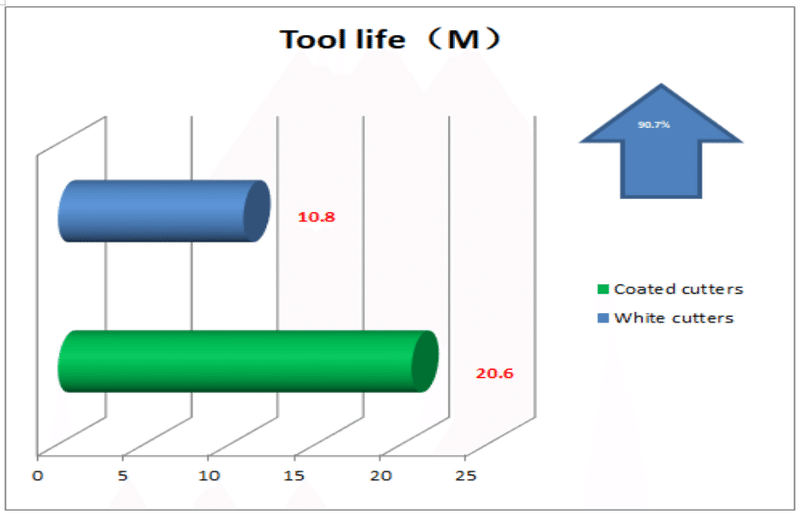

case 1 RCF1.8*10.0 armor coating cutter enhance the effect of life on machining IT158TC

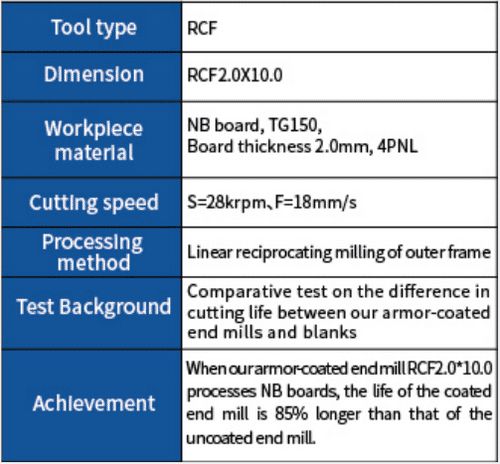

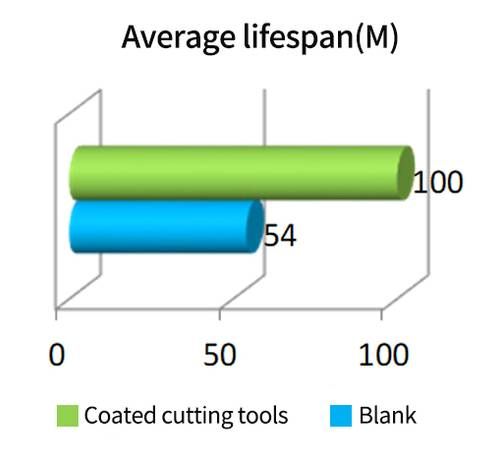

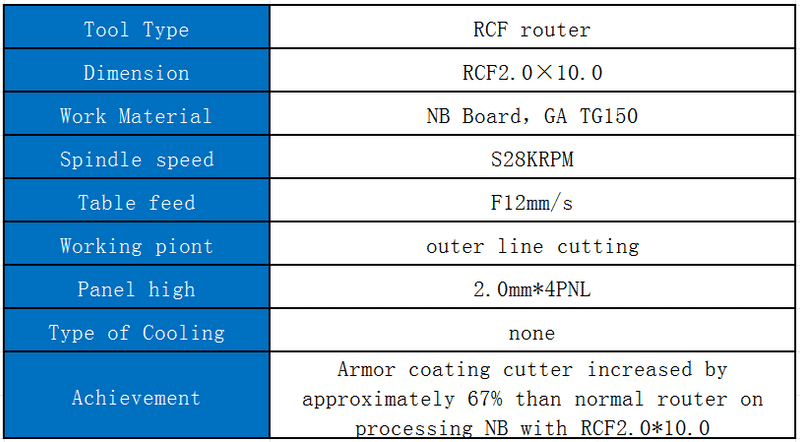

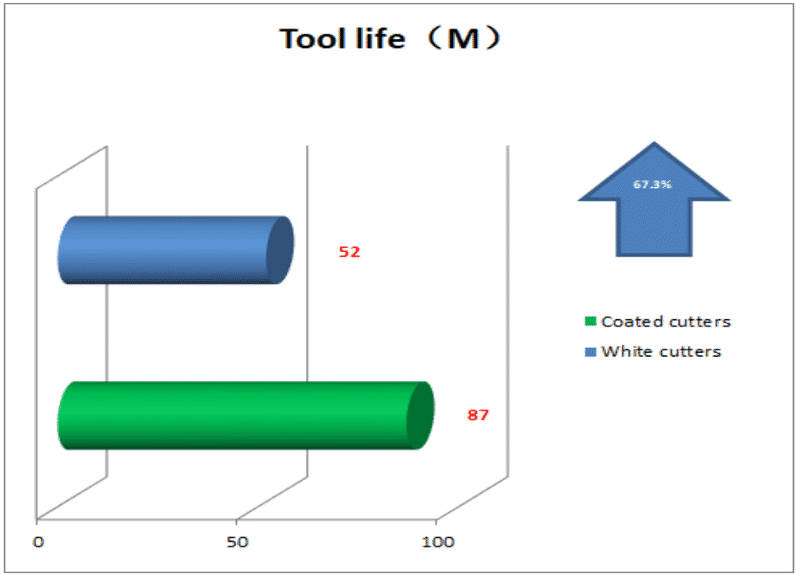

Case 2 RCF2.0*10.0 armor coating cutter enhance the effect of life on machining NB

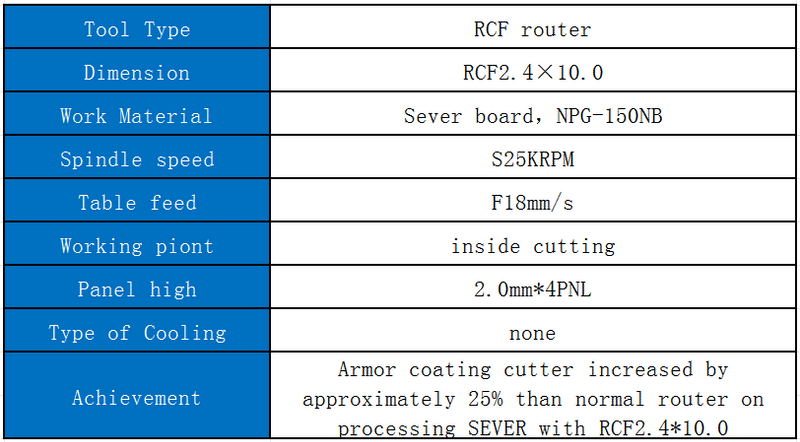

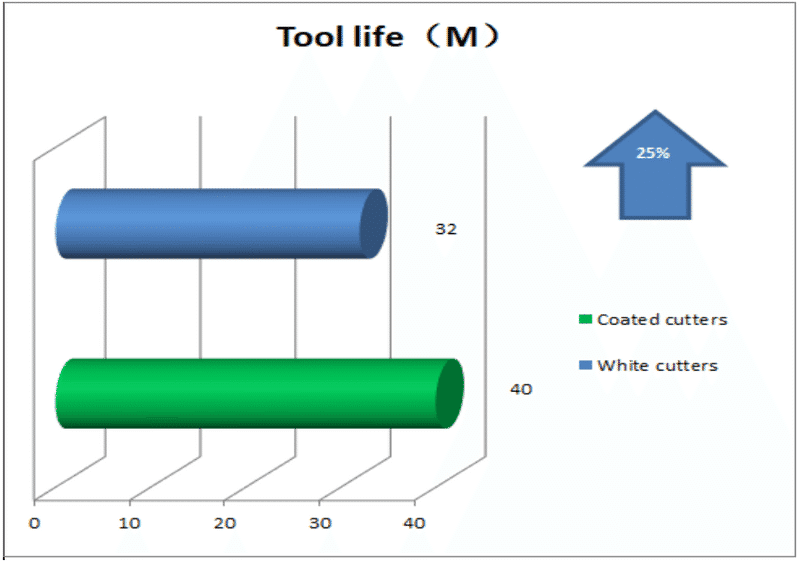

Case 3 RCF2.4*10.0 armor coating cutter enhance the effect of life on machining SEVER

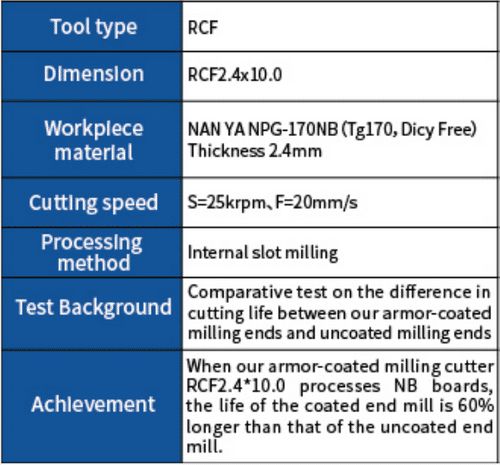

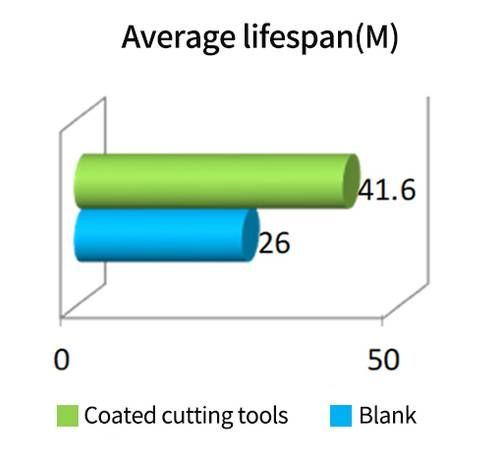

Application 4 RCF2.4*10.0 armor-coated end mill processing High-TG plate life improvement effect

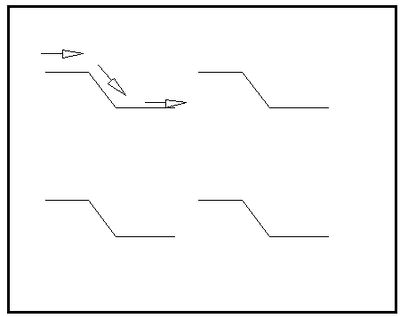

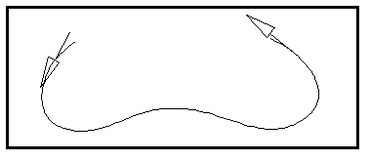

Processing Plates(the left)Processing Path(the right)

Application 5 RRC1.4*9.0armor-coated end mill processing ITEQIT158TC plate life improvement effect

Processing Plates(the left)Processing Path(the right)

Application 6 RCF2.0*10.0 armor-coated end mill processing NB plate life improvement effect